Aeron Composite Limited

Company

| Website 🔗 | |

| Business Activity | Manufacture |

| Division | Composites |

| Sub-class | Fibre-Reinforced Polymers |

| Location | Changodar, Gujarat |

| Establishment Year | 2011 |

Management

| Managing Director | Chirag Chandulal Patel |

| Educational Qualifications | 12th pass (Higher Secondary) from Gujarat Secondary and Higher Secondary Board in 2005. |

| Experience | Over 13 years of experience in the packaging, food, and composite industries. 3 years of experience specifically in the composite industry, starting in 2021 with Aeron Composite Limited. |

| Annual Salary | ₹ 88 Lakhs |

| Total Number of Employees | 791 |

About

Aeron Composite Limited is a company that specializes in the manufacture and supply of high-quality Fibre Reinforced Polymer (FRP) products. The company prides itself on delivering comprehensive solutions, encompassing conceptual design, prototype development, testing, manufacturing, logistical support, installation, and after-sales service.

FRP, a composite material, comprises a polymer matrix reinforced with fibres such as fibreglass, carbon, or aramid. This unique composition results in numerous benefits, including corrosion resistance, chemical resistance, high strength, lightweight properties, electrical and thermal non-conductivity, and ease of fabrication. These properties make FRP products highly desirable across a range of industries and applications.

Products and Services:

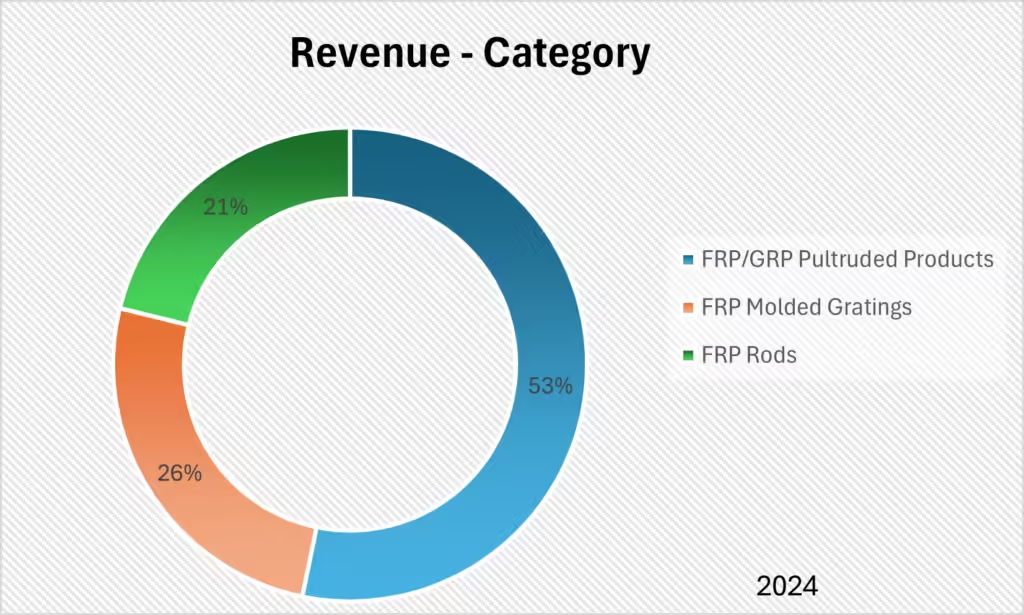

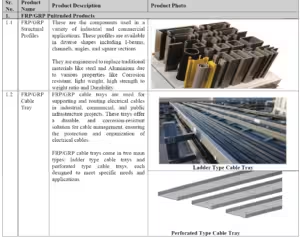

FRP Pultruded Products:

These are structural profiles used in various industries, including construction, transportation, and infrastructure. They are known for their high strength-to-weight ratio, corrosion resistance, and durability.

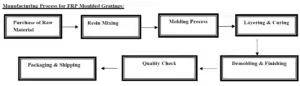

FRP Moulded Gratings:

These are used for industrial flooring, walkways, and platforms. They are resistant to corrosion, chemicals, and UV radiation, making them ideal for harsh environments.

FRP Rods:

These are used as strength members in optic fibre cables, providing support and protection to the delicate optical fibres. They are lightweight, non-corrosive, and non-conductive.

Design and Engineering Services:

The company has a team of experienced engineers and designers who provide design and engineering services for FRP products. This includes product development, structural analysis, and material selection.

Installation and Maintenance Services:

Aeron Composite Limited provides installation and maintenance services for its FRP products. This ensures that products are installed correctly and function optimally throughout their service life.

Clients:

Aeron Composite Limited serves a diverse clientele, including government entities, public sector undertakings, and major corporations. Some of the company’s key clients include:

Government Entities: ONGC Tripura Power Co. Ltd., NTPC Limited, Gujarat State Fertilizers & Chemicals Ltd., and Gujarat Narmada Valley Fertilizers & Chemical Ltd.

Public Sector Undertakings: Bharat Heavy Electricals Limited (BHEL), Indian Oil Corporation Limited (IOCL), and Oil and Natural Gas Corporation Limited (ONGC).

Major Corporations: Grasim Industries Limited, Larsen & Toubro Limited, Tata Projects Limited, and Atul Limited.

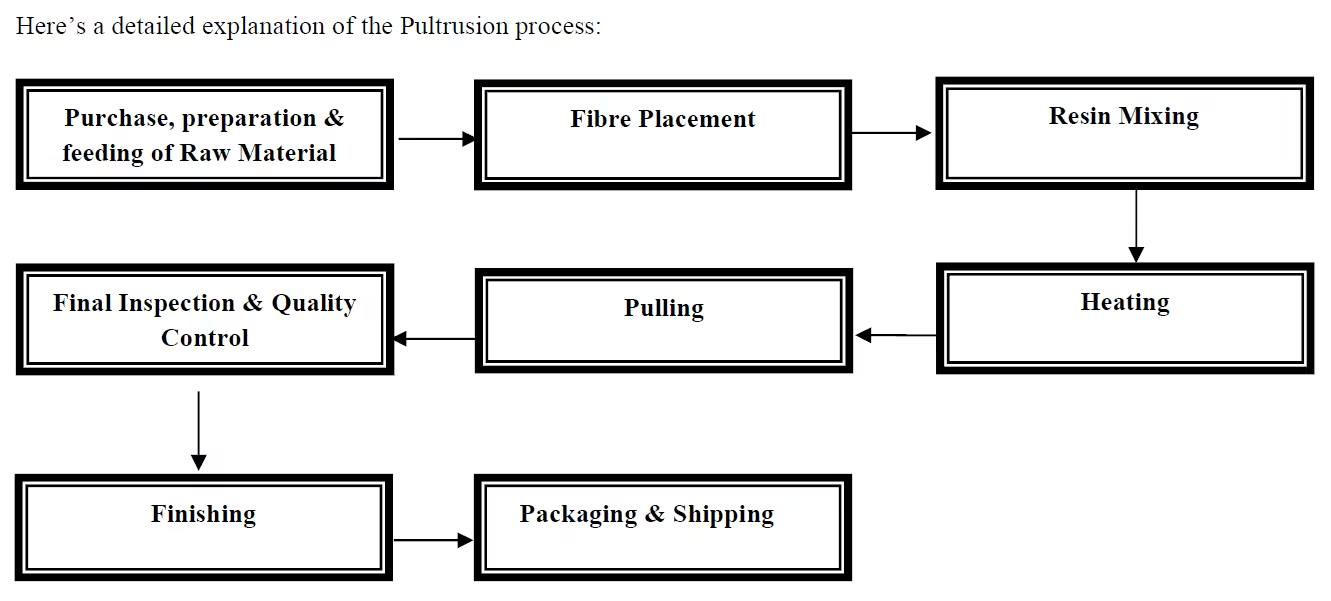

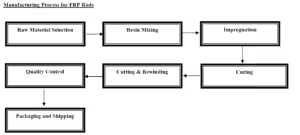

Manufacturing Process:

Conceptual Design:

The company’s engineers and designers work closely with clients to develop FRP products that meet their specific needs. This involves understanding the application, performance requirements, and environmental conditions the product will be exposed to.

Prototype Development:

Once the design is finalized, prototypes are developed to validate the product’s functionality and performance. This iterative process ensures that the final product meets or exceeds the client’s expectations.

Testing:

Rigorous testing is conducted on prototypes and finished products to ensure they meet the required quality and performance standards. The company’s testing facilities are equipped with advanced tools and technologies to perform various mechanical, chemical, and electrical tests.

Manufacturing:

The company’s manufacturing unit is equipped with state-of-the-art machinery and equipment to produce FRP products with high precision and efficiency. The manufacturing process is closely monitored to ensure adherence to quality standards and production timelines.

Logistical Support:

Aeron Composite Limited provides end-to-end logistical support, including transportation, warehousing, and inventory management. This ensures that products are delivered to clients on time and in optimal condition.

Installation:

The company has a team of skilled technicians who provide installation services for its FRP products. This ensures that products are installed correctly and function as intended.

After-Sales Service:

Aeron Composite Limited is committed to providing prompt and efficient after-sales service to its clients. This includes addressing any product-related queries or concerns, providing maintenance support, and ensuring customer satisfaction.

Raw Materials:

Fibreglass Roving:

This is a collection of glass fibres bundled together to provide strength and reinforcement to the FRP material.

Fiberglass Mats:

These are non-woven mats of glass fibres used to add thickness and impact resistance to FRP products.

Resins:

These are the polymer matrix that binds the fibres together. The type of resin used depends on the desired properties of the final product. Common resins include polyester, vinyl ester, and epoxy.

Additives:

These are added to the resin to enhance its properties or impart specific characteristics to the final product. Examples include pigments, UV stabilizers, and fire retardants.

Suppliers:

Domestic Suppliers: Several domestic suppliers provide raw materials such as fibreglass roving, mats, and resins.

International Suppliers: The company also sources raw materials from international suppliers, particularly speciality resins and additives.

Other Key Aspects:

The unit is accredited with ISO 9001:2015 certification, covering the design, manufacturing, and supply of a wide range of FRP products

The company’s commitment to excellence has also earned it the recognition of ‘Two Star Export House‘ in accordance with the provisions of the Foreign Trade Policy 2023.

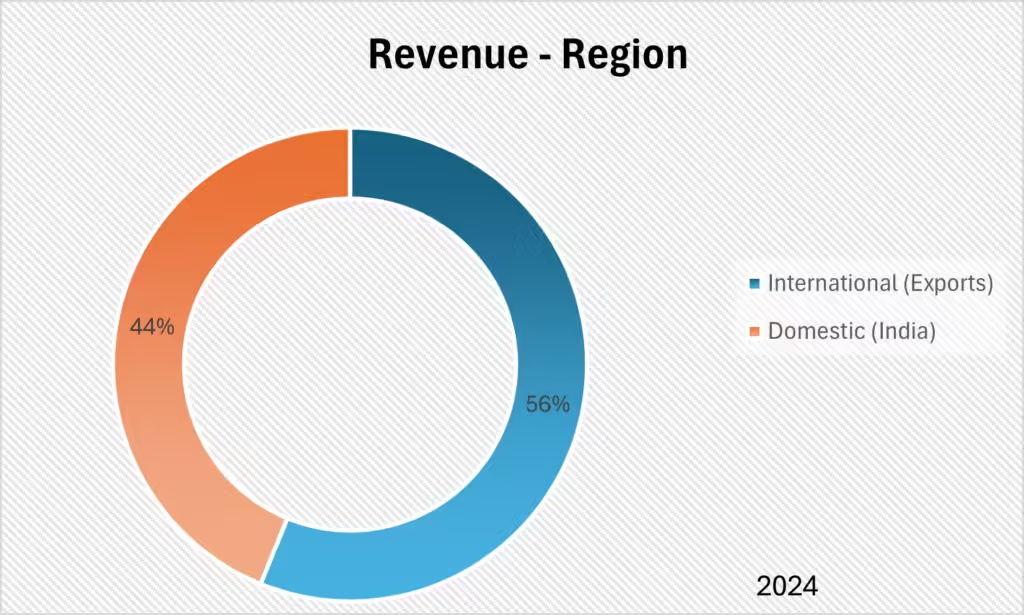

Domestic Sales: Sales of FRP products within India, contributed to 43.84% of the total revenue for the period ending on February 29, 2024.

International Sales: Sales of FRP products to over 30 countries across the globe, contributing to 56.16% of the total revenue for the same period.

Manufacturing Process Flowchart

Revenue – Category

Revenue – Region

Audit and Legal

Auditor’s Remarks:

The auditors did not make any material remarks or qualifications about the company’s financial information. Sources and related content

Non-Compliances and Other Issues:

GST Return Filing Delays:

The company has incurred penalties for delays in filing GST returns in the past. These penalties were due to operational reasons and have been rectified.

Contingent Liabilities:

As of February 29, 2024, the company’s total contingent liabilities amounted to Rs. 781.31 lakhs. These liabilities primarily include:

- The estimated amount of contracts remaining to be executed on the capital account and not provided for Rs. 718.61 lakhs

- Guarantees given by banks on behalf of the company: Rs. 62.70 lakhs

Legal Cases:

Cases Filed Against the Company

Cases Filed by the Company

| Nature of Cases | No. of Outstanding Cases | Amount in dispute/demanded to the extent ascertainable (₹ in lakhs) |

| Criminal Proceeding | 2 | 44.85 |

| Other Litigation | 5 | 131.37 |

| Total | 7 | 176.22 |

Cases filed by Promoters and Directors:

| Nature of Cases | No. of Outstanding Cases | Amount in dispute/demanded to the extent ascertainable (₹ in lakhs) |

| Other pending material Litigation | 2 | 4.33 |

Tax Proceedings against the Company:

SWOT Analysis

Strengths

| Strong revenue growth and profitability: The company has demonstrated a consistent track record of revenue growth and profitability, indicating its strong financial performance and potential for future success. |

| Diverse revenue streams: The company generates revenue from both domestic and international markets, reducing its reliance on any single market and mitigating risks associated with market fluctuations. |

| Comprehensive solutions: The company provides a wide range of services, including design, manufacturing, installation, and after-sales support, offering a one-stop solution for customers’ FRP product needs. |

| Focus on quality: The company’s manufacturing unit is ISO 9001:2015 certified, ensuring high-quality products and services that meet international standards. |

| In-house R&D unit: The company has a dedicated R&D unit, enabling it to develop innovative products and processes that cater to the evolving needs of its customers. |

Weaknesses

| Dependence on contract labour: The company relies heavily on contract labour, which can be a source of uncertainty and potential operational disruptions. |

| Limited long-term contracts: The company does not have long-term contracts with its suppliers, potentially affecting the stability of raw material supply and pricing. |

| Capital-intensive nature: The FRP products manufacturing business requires significant capital investments, potentially limiting the company’s flexibility in responding to market changes or pursuing growth opportunities. |

Opportunities

| Growing FRP market: The global FRP market is expected to grow significantly in the coming years, driven by increasing demand from various industries, presenting opportunities for the company to expand its market share and revenue. |

| Expansion into new markets: The company can explore opportunities to expand its presence in new geographic markets, both domestically and internationally, further diversifying its revenue streams and reducing reliance on existing markets. |

| Product diversification: The company can diversify its product portfolio by developing new and innovative FRP products that cater to the evolving needs of its customers and tap into new market segments. |

Threats

| Competition: The company faces competition from both domestic and international players in the FRP market, which could pressure its pricing and market share. |

| Raw material price fluctuations: The prices of raw materials used in FRP production can fluctuate significantly, impacting the company’s profitability and financial performance. |

| Economic slowdown: A slowdown in the domestic or global economy could adversely affect the demand for the company’s products and services, impacting its revenue and profitability. |

Porter’s Five Forces1

| Threat of New Entrants | MODERATE |

| While the FRP industry requires significant capital investment and technical expertise, there are still many smaller players, particularly in the unorganized sector, that could potentially increase competition. The government’s efforts to promote the industry may also attract new entrants. |

| Bargaining Power of Suppliers | MODERATE |

| The company sources raw materials from both domestic and international suppliers. While the company has a few key suppliers, it does not have long-term contracts with them, potentially exposing it to price fluctuations and supply disruptions. |

| Bargaining Power of Buyers | MODERATE |

| The company serves a diverse clientele, including government entities, public sector undertakings, and major corporations. However, some customers, particularly larger corporations, may have significant bargaining power due to the volumes they procure. |

| Threat of Substitute Products or Services | LOW – MODERATE |

| FRP products offer several advantages over traditional materials such as steel and aluminium, including corrosion resistance, lightweight properties, and ease of fabrication. However, there are still some applications where traditional materials may be preferred due to cost or other factors. The company’s focus on innovation and developing new FRP applications can help mitigate this risk. |

| Rivalry Among Existing Competitors | HIGH |

| The FRP market is fragmented and competitive, with both organized and unorganized players. Competition is based on factors such as product quality, price, delivery, and customer relationships. |

Peer Comparison

There are no listed companies in India that engage in a similar business.

Green Box

IPO Funds:

Expenditure Requirements for an Additional Manufacturing Unit:

The company plans to expand its manufacturing capabilities by setting up an additional manufacturing unit. This expansion aims to increase the production capacity of existing products and introduce new product lines, including FRP Rebars and Carbon Fiber Reinforced Polymer (CFRP) products such as CFRP Core Rods, CFRP Planks for Wind Blades, CFRP Pultruded Profiles, and Molded Parts.

Increased Production Capacity:

The company plans to increase its manufacturing capacity for existing products like FRP Moulded Gratings and FRP Rods by 70% to 75% of the total installed capacity. This will enable the company to cater to the growing demand from its existing customers and attract new clients.

Economies of Scale:

By expanding its production capacity, the company aims to achieve economies of scale, further reducing production costs and improving its overall financial performance.

Renewable Energy Integration:

The company plans to install a 2400 KW solar power plant at the new manufacturing unit.

Positive Operating Cash Flow:

Aeron Composite Limited has maintained a positive operating cash flow in the past years.

Participation in Industry Events:

The company actively participates in national-level industry events and exhibitions, such as AIA Expo 2024, Chemtech World Expo, Dahej Industrial Expo, and IFAT Mumbai. These events provide a platform to showcase the company’s products and services to a wider audience, including potential customers and partners.

Industry Outlook:

The Indian composites market is expected to reach an estimated value of US$ 1.9 billion by 2026, with a CAGR of 16.3% from 2021 to 2026.

The global composites market size is projected to grow from USD 74.0 billion in 2020 to USD 112.8 billion by 2025, at a CAGR of 8.8%. The composites industry is growing due to the rise in demand for high-performance materials, globally.

Amber Box

Capacity Utilization:

As of February 29, 2024, Aeron Composite Limited’s current capacity utilization rate is 61.32%

Red Box

Reliance on Contract Labour:

The company’s operations are heavily reliant on contract labour. This dependence can lead to uncertainties related to labour availability, skill levels, and potential labour unrest, which could disrupt operations and impact productivity.

Raw Material Price Volatility:

The prices of raw materials used in FRP production are subject to significant fluctuations, which could impact the company’s profitability and financial performance.

Capital Intensive Operations:

The company’s operations are significantly capital-intensive, requiring substantial investments in machinery and equipment. This can limit the company’s financial flexibility and make it vulnerable to economic downturns or industry-specific challenges.

Images

- The force value of “LOW” is considered good Click Porter’s Five Forces article for more information. ↩︎

Disclaimer: The above information/document is based on publicly available sources and has been issued solely for educational and informational purposes and should not be considered as investment advice or as a Buy/Sell recommendation, or as a research report. Although due diligence has been done to ensure the accuracy of the data presented, the website or authors are not responsible for any decision arising out of an inadvertent mistake or error in the data presented on the website. The authors may also have equity shares in the companies mentioned in this report adhering to provisions of regulation 16 of the Securities and Exchange Board of India (Research Analysts) Regulations, 2014. The investor is advised to consult his/her investment advisor and undertake further due diligence before making any investment decision in the companies mentioned. Authors are not liable for any financial gains or losses due to investments made as per the information provided on this website (StocKernel.com).

Good research!